Technical specifications for Motorcycle Trike Tricycle Car

| Chongqing Tengtian Group | ||||||

| Product Name: | New Motorcycle Trike Tricycle Car | |||||

| FOB Price: | 800$ USD ~1500$ USD Â (CHONGQING,CHINA) | |||||

| Product Technical  Specifications | ||||||

| Technical  Design | Application | Cargo | ||||

| Design  Max Speed | >60km/h | |||||

| Loading  Capacity | >1t | |||||

| Unladen  Kerb Weight | 320kg | |||||

| Dimension(L*W*H) | 3200mm*1250mm*1450mm | |||||

| Color | Red/Green/Yellow/Black/Other colors | |||||

| Track | 1050mm | |||||

| Wheel  Base | 2100mm | |||||

| Ground  Clearance | 160mm | |||||

| Brake  Mode | Front&Back wheels, Drum | |||||

| Transmission | Shaft Drive | |||||

| Power | 8.0 kw | |||||

| Cool  Type | Air cooled | |||||

| Min.Fuel  Conumption | 354g kw.h | |||||

| Fuel  Type | Gasoline | |||||

| Fuel  Tank Capacity | 12 L | |||||

| Operation | Starting System | Electric/Kick | ||||

| Transmission | 5 Forward &1 Reserse  Gears | |||||

| Gearshift  Control | Manual-Foot | |||||

| Clutch  Method | Manual-Hand | |||||

| Brake  Operate Mode | Manual-Hand or Foot | |||||

| Â | Â | |||||

| Engine  Details | Engine Type | Singlecylinder,4-stroke,camshaft  downward | ||||

| Bore  Stroke | 63.5×49.5mm | |||||

| Fuel  Type | Gasoline | |||||

| Compression  Ratio | 9.5:1 | |||||

| Rated  Power&Rotating Speed | 8.0KW /8000rpm | |||||

| Max.Torgue/Rotating  Speed | 11.0N.m /6500rpm | |||||

| Lowest  No-Load Speed Stability | 1500rpm | |||||

| Displacement(cc) | 200cc | |||||

| Ignition  System | CDI | |||||

| Apply  to | Motor tricycle | |||||

| Starter | Kick/Electric | |||||

| Packing | Transport | By Land/Sea/Other | ||||

| Port  Of Loading | Chongqing/Shanghai/Other  ports of china | |||||

| Package | Protective Packaging | |||||

| Loading  Capacity (CKD) | 24 units in 20"GP,60 Units in 40"HQ | |||||

| Delivery  Time | 15-20 Days after receiving  prepayment | |||||

| Â |

|

| ||||

Please Note: | ||||||

Economic and easy to use

1. Humanized configuration: Motorized tricycles replaced traditional labor force transportation, more convenient and  faster, save your costs both on energy and time. Especially very powerful and useful when transporting large and heavy goods and driving roads with serious condition.

2. Low maintenance: With correct using, the robust and reliable body & power source of tricycles will keep health for a long time. Do not need to maintain frequently. Daily inspection and cleaning can be easy finished by yourselves  in your garden or before your house door. All these require little maintenance fee.

3. Wide range of application: Allows transporting grain, bullamacow, fertilizer, water, silt, coal, metals, wood, fruit,  a  quatic product, passengers and more, as long as you can think and you need. With one tricycle in your house, it will be your good helper both on daily life and work. Therefore it is very effective and productive.

4. Ready to use: The operating system of cargo tricycle is very easy to handle, and much closer to common users. its simplicity allows many operators to use without in-depth training.

Â

Tricycles vary from size to color

Displayed here is a selection of some of the tricycles that we have produced in the past. This is a mere fraction of the production we have done in the past and it means to give a brief introduction to our range of capabilities and experience. If you require a tricycle you do not see here, please contact us as this is just an example of our product and we can do much more.

Pacakge & Delivery

Normally, our tricycles take SKD / CKD and carton packaging. Different parts with different packaging methods. If you  have special requirements, please mention that in advance. Please see our main packaging methods as following:

Why should you choose us?

1. We Tengtian Technological offer outstanding products:

High quality and reasonable price.

Strong power and low engine consumption.

Stable and durable frame for cargo tricycle.

Electrophoresis dipping process paint, anti-corrosion ability is significant, ensure color durability.

Super loading ability, suitable for bad or mountain roads driving.

Â

2. Choose us Tengtian Group, you can get:

Professional quality control system, ensure each part with our best quality.

Perfect production assembly line, ensure delivery on time.

Outstanding export teamwork, ensure thorough after-sale services.

Specialized in cargo tricycles design, manufacture and export more than 8 years, had built an     excellent businessÂ

Well know about foreign market, especially South America, Africa, Southeast Asia, and Middle East.

Do our best, be your best" is our aim. Your trust, we treasure.

Contact us

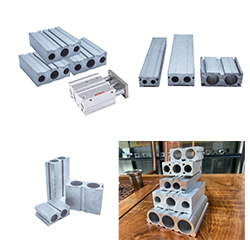

TCN/TN Pneumatic Cylinder Barrel

Guided pneumatic cylinder adds another guided rod on the basis of the single rod or double rod cylinders to make the movement trajectory of the cylinder more accurate, which can effectively increase the performance of resisting side load and reduce the influence of lateral swing. Most regular guided air cylinder is MGP series.Pneumatic Cylinder Tube.

Both dual rod air cylinder and guided air cylinder have a magnetic ring inside, which is convenient for the magnetic switch to detect the position of the piston movement. There are mounting holes on three sides of the fixed plate of double rod air cylinder and guided pneumatic cylinder, which are convenient for multi-directional installation and use.Air Cylinder Barrel.

Parameter:

â—† Working pressure: 0.15~0.7MPa

◆ Ambient temperature: -20~70℃

â—† Applicable fluid medium: Compressed air, non-corrosive gas

â—† Operating speed: 50-500mm/s

A three-axis cylinder typically refers to the use of three independent linear cylinders in a system to achieve motion in three-dimensional space. In automation and robotics technology, such configurations can be used to achieve precise position control and object movement. Each cylinder is typically responsible for one axial movement (e.g. X, Y, Z).

Here are some key points about three-axis cylinders:

Structure:

Usually composed of three independent linear cylinders.

Each cylinder is installed in a mutually perpendicular direction, forming a three-dimensional coordinate system.

Application:

Part positioning on automated assembly lines.

Position adjustment of end effectors in industrial robots.

Accurate movement in material handling systems.

Sample processing in laboratory equipment.

working principle:

By compressing air, the piston is pushed to move inside the cylinder.

The extension and contraction of the piston rod drives the mechanical structure to move along a specified axis.

The combined motion of three axes can achieve complex spatial trajectories.

Control system:

PLC (Programmable Logic Controller) or specialized motion controller may be required to coordinate the actions of the three cylinders.

Sensors are used to provide feedback on position information to ensure precise control.

characteristic:

Compact structure, suitable for application environments with limited space.

Quick action, suitable for high-speed operation scenarios.

Maintenance is relatively simple because the main components are pneumatic.

Dual axis cylinder usually refers to a specially designed pneumatic actuator that can generate motion in two directions. This type of cylinder is typically used in applications that require linear motion on two axes simultaneously or separately. Here is some basic information about dual axis cylinders:

Basic concepts

Definition: A dual axis cylinder is a pneumatic component capable of producing linear motion on two axes simultaneously or separately.

Application: Widely used in automated production lines, material handling, precision positioning, and other situations that require multi axis control.

Structure and Type

Parallel dual axis cylinder: Two cylinders are arranged in parallel, and the piston rod can move synchronously or independently.

Coaxial dual axis cylinder: Two cylinders share a piston rod and control the movement of the two shafts through different air paths.

Other types: There are also specially designed dual axis cylinders, such as dual piston rod cylinders, which can install two piston rods on one cylinder block.

working principle

Compressed air drive: By using compressed air to push the piston inside the cylinder, it drives the piston rod or connecting piece to move along a predetermined axis.

Independent or synchronous control: Depending on the needs, the motion of each axis can be independently controlled, or two axes can be synchronized through specific design.

Control system

Electromagnetic valve: used to control the direction of airflow, thereby controlling the expansion and contraction of the cylinder.

Sensors: Displacement sensors or proximity switches can be installed to monitor the position of the piston and achieve precise control.

PLC or controller: It is usually necessary to coordinate the working sequence and speed of the cylinders through PLC or other controllers.

Application examples

Automated assembly: Dual axis cylinders can be used for positioning, clamping, or assembling parts.

Robot arm: As a part of the end effector of the robot, it achieves grasping and placing tasks.

Testing equipment: used in laboratories or quality control environments to simulate pressure or thrust testing.

characteristic

Compact: Compared to using two cylinders separately, dual axis cylinders have an advantage in space occupation.

Flexibility: Different travel lengths and installation methods can be customized according to application requirements.

Economy: Reduce installation space and costs while maintaining high performance.

TCN Pneumatic Cylinder Barrel,TN Pneumatic Cylinder Barrel,Dual Rod Air Cylinder Aluminum Tube,Dual Rod Air Cylinder Tube

Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com